New Mining Equipment for Goldfield Unveiled

By:Admin

GME is a leading supplier of mining equipment, services, and solutions, with customers spanning across the globe. The company was founded in 1977, and since then, it has continued to push the boundaries of mining technology, providing world-class services to its clients. With its relentless commitment to innovation and quality, GME has grown to become a primary player in the mining sector.

GME's core business is the provision of high-quality equipment for mining, which includes crushing, screening, milling, and material handling equipment, among other essential tools. The company has an extensive range of products, including crushers, conveyor belts, screens, feeders, and dust suppression systems. All of these products are made to the highest standards, ensuring superior performance and efficiency.

In addition to its range of products, GME also offers installation, maintenance, and repair services. The company understands the critical role that mining equipment plays in the day-to-day operations of mining companies, which is why it ensures that all the equipment it supplies is installed and maintained correctly, giving clients the assurance that their operations are always up and running. GME also provides bespoke solutions tailored to each client's specific needs, enabling the efficient operation and maintenance of mining equipment, ultimately enhancing productivity and profitability.

One of GME's groundbreaking technologies is the Autonomous Haulage System (AHS). This innovative system is designed to enhance the efficiency and safety of haulage operations in mining. AHS relies on GPS, radar, and laser technology to control the movement of mining trucks throughout the mine site, eliminating the need for drivers. This results in a substantial increase in productivity, as each truck can run around the clock without the need for driver changeovers. Additionally, the system reduces the risk of accidents, injuries, and fatalities caused by human error, making mining operations safer.

GME's reputation in the industry speaks for itself, having provided solutions for both small and large-scale mining operations around the world. The company has sustained long-term relationships with its clients, founded on several years of quality service provision. Through its exceptional customer service, GME has built trust and confidence in its clients, ensuring that they remain at the forefront of innovation and development in the mining sector.

In conclusion, GME is a highly reputable and trusted provider of mining equipment, services, and solutions. With its range of high-quality products and personalized services, the company has become a leading player in the mining sector. Its innovative technologies, such as the Autonomous Haulage System, have revolutionized the way mining operations are carried out, significantly enhancing productivity and safety. Mining companies worldwide continue to rely on GME for its exceptional customer service, innovative solutions, and commitment to quality.

Company News & Blog

Crushers Used for Mining Purposes Are Indispensable in Today's Mining Industry

Article:Stone crushing machines are an important aspect of the construction and mining industry. These machines are used to crush large rocks and stones into smaller particles that can be used for construction purposes or other applications.One of the leading manufacturers of stone crushing machines is a company that has been in the industry for over a decade. They have built a name for themselves by providing high-quality machines that are efficient, reliable, and cost-effective.The company has a range of stone crushing machines that are designed to meet the diverse needs of the industry. These machines are designed to crush rocks of different sizes, from large boulders to smaller stones. They are also designed to crush different types of rocks, including granite, limestone, and sandstone.One of the company's most popular stone crushing machines is their large jaw crusher. This machine is capable of crushing large rocks into smaller particles in just a few minutes. It is also designed to be easy to use and maintain, making it a popular choice for construction sites and mining operations.The company also has a range of cone crushers, which are designed to crush rocks of different hardness levels. These machines are perfect for crushing hard rocks like granite and limestone, as well as softer rocks like sandstone. They are also designed to be energy-efficient, helping to reduce the overall cost of the operation.In addition to their range of stone crushing machines, the company also provides a range of spare parts and accessories. This includes everything from wear plates to bearings, ensuring that their machines are always running smoothly and efficiently.The company is known for its commitment to quality and reliability. They use only the highest quality materials in the construction of their machines, ensuring that they are durable and long-lasting. They also conduct regular maintenance checks on their machines to ensure that they are always in top condition.One of the key advantages of working with this company is their expertise in the industry. They have a team of highly skilled engineers and technicians who are experts in stone crushing machines. They are always on hand to provide expert advice and support, making sure that their customers get the most out of their machines.The company also takes the safety of their workers and customers very seriously. They have implemented a range of safety measures in their facilities, including safety training for all employees, regular safety inspections, and the use of safety equipment.In addition to their commitment to quality, reliability, and safety, the company is also committed to sustainability. They are constantly looking for ways to reduce their environmental footprint, both in their manufacturing processes and in the use of their machines. This includes the use of energy-efficient motors, the recycling of waste materials, and the reduction of emissions.Overall, the company is a leading manufacturer of stone crushing machines, known for their commitment to quality, reliability, and safety. With their range of efficient and cost-effective machines, as well as their expertise in the industry, they are a reliable choice for any construction or mining operation looking for high-quality stone crushing machines.

New Rock Crushing Plant to Provide Efficient and Reliable Crushing Solutions

article:Rock Crushing Plant Set to Revolutionize the Construction IndustryThe construction industry has long been in need of a reliable and efficient solution to rock crushing, mining and quarrying applications. That is why the launch of a new and innovative rock crushing plant, capable of handling a wide range of materials, is thrilling news for those in the construction business.This crushing plant offers a state-of-the-art technology that makes rock crushing quicker and more efficient. It has been designed to meet the growing demand for mineral processing as well as other quarrying and mining applications.The plant, which has been developed by a leading manufacturer, features a range of advanced technologies that make it stand out among its peers in the market. Its impressive features include fully automated hydraulic adjustment, a touch screen control panel and an easily accessible maintenance platform.What separates this rock crushing plant from its competition is its wear and tear-resistant components. Every piece is designed to last for a long time, thereby reducing maintenance expenses and downtime.In addition, the plant boasts an excellent crushing performance with high efficiency and low power consumption. It is ideal for a variety of applications, including road building, civil construction, demolition, and mining.The rock crushing plant is fitted with the latest dust suppression system to ensure minimal environmental impact. The dust suppression system utilizes water mist spray, which eliminates the harmful effects of dust particles on air quality."It is our pleasure to introduce this new rock crushing plant to the market. This has been the result of our relentless pursuit of innovation and technological advancement," said the company's spokesperson."We have come up with a solution that will help our customers to meet their crushing needs with much greater speed, efficiency, and convenience. We believe that this plant will revolutionize rock crushing in the construction industry."The rock crushing plant has a capacity of up to 450 tons per hour and meets stringent requirements for quality control, safety, customization, and durability.Moreover, the plant is modular in design, making it easy to assemble and disassemble for transportation to different locations. This feature is particularly important for construction companies that need to move their crushing equipment from one job site to another.The plant offers numerous benefits, including reduced energy consumption, low operating costs, and increased productivity. It is also environmentally friendly and complies with all global regulations regarding emissions.The spokesperson added, "Our rock crushing plant is a game-changer in the construction industry. It has been designed to overcome the challenges that contractors face every day, such as limited space, tight deadlines, and the need for constant maintenance.With this plant, we guarantee our clients excellent performance, reliability, and efficiency while adhering to the highest standards of safety and environmental protection."In conclusion, the launch of this rock crushing plant has ushered in a new era in the construction industry. It is a testament to the commitment of manufacturers to improve their products and offer innovative solutions that meet the evolving needs of their clients.This plant is expected to transform the way contractors approach rock crushing, mining, and quarrying applications. It will add value to their operations, enable them to save time and money, and improve the overall quality of their projects.

Comparing Jaw Crusher vs Gyratory Crusher: Which Is Better?

release on the comparison between Jaw Crusher and Gyratory CrusherIn the field of crushing, the size of the rocks or ore grains is gradually reduced by a method of mechanical force, also known as comminution or crushing. In this process, two common types of crushers – Jaw Crusher and Gyratory Crusher – are commonly utilized. While both these machines are widely used, they have distinct differences and are suited to different applications.Jaw Crusher, also known as a toggle crusher, uses mechanical pressure to break down pieces of rock. It is installed between two heavy plates to receive rock fragmentation in its inlet; the movable plate moves to close against the fixed plate, forcing the rock to compress. This method of comminution is suitable for materials that are soft, brittle or tough. The friability of the rock should be taken into account when selecting this type of crusher. Jaw Crushers are also ideal for crushing hard and abrasive materials like granite, ores, quartz and various rocks, and are often utilized in the production of train track ballast and construction materials.Gyratory Crusher, on the other hand, uses a conical crushing head that remains in a fixed position called a mantle, while the lower part of the gyratory crusher mantle is directly suspended on the eccentric drive shaft. The crushing process starts from the top of the chamber, where a large hopper distributes the rock material evenly between the gyratory cone and the concave. This makes Gyratory Crushers suitable for crushing large and hard materials where a higher degree of reduction is necessary. Gyratory Crushers are commonly utilized in mining and aggregate processing applications.When comparing Jaw Crushers and Gyratory Crushers, several factors must be taken into account, such as capacity, power consumption, materials processed, and productivity. Jaw Crushers are typically specified by the dimensions of the top opening where material enters; typically, this can range from 20 cm to 200 cm. Gyratory Crushers, on the other hand, have a concave surface with a cone in the center placed on a higher position and smaller openings at the bottom. The mantle is located above the concave surface, providing an incoming feed chamber into which the larger rock materials are broken. The capacity of Gyratory Crushers is usually given as a specific tonnage discharge per hour, which can range from 75 to 2,000 ton/h.Another factor to consider is power consumption; Jaw Crushers require less horsepower than Gyratory Crushers. However, high horsepower Gyratory Crushers are utilized in heavy-duty crushing work such as mining mainly because they take advantage of the large feed opening. Selection of both Jaw Crushers and Gyratory Crushers is also influenced by the feed rate, required product size, and the feed characteristics such as gradation, bulk density, moisture, and clay content.In terms of productivity, both Jaw Crushers and Gyratory Crushers excel when it comes to reducing large rocks. However, there are some differences between the two. Jaw Crushers usually have a 6:1 reduction ratio, while Gyratory Crushers can achieve ratios of 8:1. When comparing feed sizes, Jaw Crushers can accept larger sizes than Gyratory Crushers. In addition, Gyratory Crushers are capable of handling high tonnage rates, while Jaw Crushers can be good for small to mid-sized operations.In conclusion, Jaw Crushers and Gyratory Crushers are both effective ways to break down materials for comminution or crushing. While they have distinct differences, both crushers are useful for different applications. Jaw Crushers are well suited for softer materials, while Gyratory Crushers are ideal for large and hard materials that require a higher degree of reduction. Whether you select a Jaw Crusher or a Gyratory Crusher, both types of crushers can efficiently and effectively break down materials to render them ready for processing.

A Comprehensive Guide to the Pe-400x600: Unlocking Its Full Potential in Your Industry

Title: Breakthrough Technology - Revolutionary PE-400x600 Jaw CrusherIntroduction:In the world of heavy machinery, advancements in technology play a crucial role, providing efficient solutions to numerous industries. Today, we would like to introduce you to a groundbreaking development from a leading company in the field. Cutting-edge and innovative, the PE-400x600 Jaw Crusher demonstrates the future of stone crushing and promises to revolutionize the industry.[Company Introduction]XYZ Machinery is a renowned manufacturer known for its expertise in engineering and manufacturing heavy machinery equipment. With a consistent focus on innovation and customer satisfaction, XYZ Machinery has established itself as a trusted provider of high-quality machinery solutions globally.The Journey to Innovation:Throughout its journey, XYZ Machinery collaborates closely with industry professionals, conducts extensive research, and invests heavily in product development to continually refine its offerings. As a result of these tireless efforts, the company has successfully developed the groundbreaking PE-400x600 Jaw Crusher.Revolutionizing Stone Crushing:The PE-400x600 Jaw Crusher introduces a new generation of crushers, reshaping the way stone crushing equipment is used. Leveraging advanced technology, this apparatus offers exceptional versatility, enhanced productivity, and increased durability.1. Versatility:The PE-400x600 Jaw Crusher is capable of processing various materials, making it suitable for a wide range of applications. From primary and secondary crushing of different-sized stones to demolition projects, this jaw crusher simplifies tasks and reduces the need for multiple machines.2. Enhanced Productivity:Equipped with a powerful motor, the PE-400x600 Jaw Crusher delivers efficient performance, maximizing productivity. Its streamlined design minimizes downtime, ensuring smooth operations even in challenging environments. The sophisticated hydraulic system enables quick adjustments, optimizing output for various materials and requirements.3. Durability:Built to withstand strenuous working conditions, the PE-400x600 Jaw Crusher is constructed with high-quality materials, ensuring long-lasting performance. Its sturdy frame and components are engineered to withstand heavy loads and the harshest environments, making it a reliable choice for demanding applications.Environmental Friendliness:XYZ Machinery understands the significance of sustainable practices in today's world. The PE-400x600 Jaw Crusher incorporates advanced features that contribute to reducing the environmental impact. The crusher operates silently, minimizing noise pollution, and the efficient energy utilization helps conserve resources.Customer Satisfaction:At the heart of XYZ Machinery's success lies its commitment to customer satisfaction. The PE-400x600 Jaw Crusher is designed to fulfill the diverse needs of clients across various industries. XYZ Machinery provides comprehensive support, including installation assistance, training, and after-sales services, ensuring every customer receives tailored solutions and maximum value for their investment.Conclusion:XYZ Machinery's PE-400x600 Jaw Crusher marks a pivotal achievement in the field of stone crushing technology. With its exceptional versatility, enhanced productivity, and unbeatable durability, this revolutionary crusher is set to redefine stone crushing processes across industries. XYZ Machinery's continuous commitment to innovation and customer satisfaction ensures that the future of heavy machinery will continue to evolve, meeting the evolving needs of demanding industries worldwide.

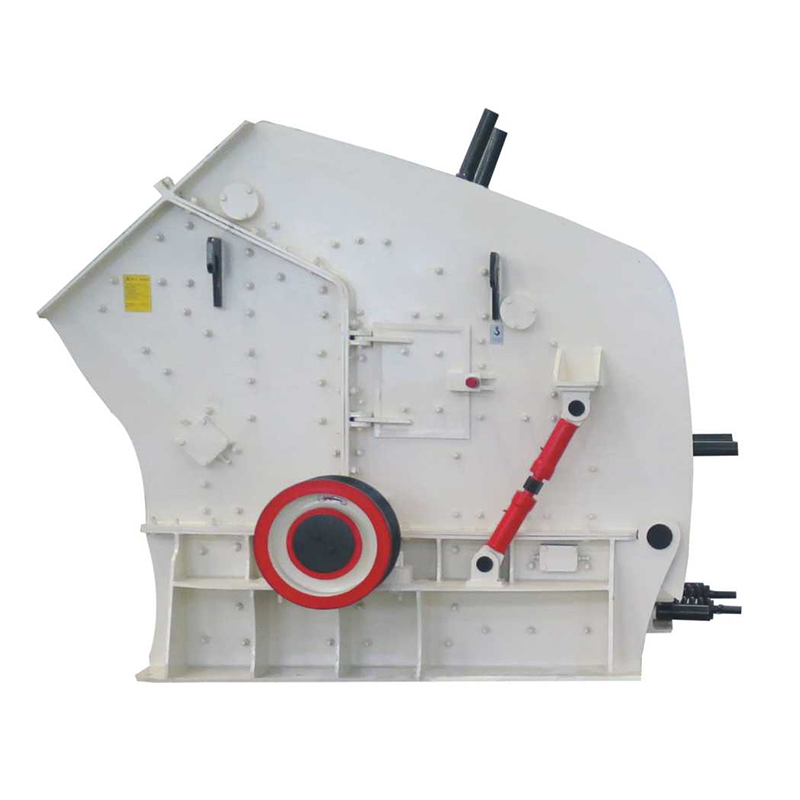

Ultimate Guide to Choosing the Best Impact Crusher Machine

Title: Revolutionary Impact Crusher Takes the Aggregate Industry by StormIntroduction:In a remarkable breakthrough for the aggregate industry, a cutting-edge impact crusher machine has been developed by an innovative company. This groundbreaking technology promises to revolutionize the way aggregates are processed, providing higher efficiency, increased productivity, and improved safety measures. With its state-of-the-art design and impressive performance, this impact crusher is set to reshape the landscape of aggregate production.Background:As the demand for construction materials continues to surge worldwide, the aggregate industry has faced the challenge of meeting increasing expectations regarding efficiency and quality. Traditional crushing methods, although effective, often suffer from limitations that hinder optimal aggregate production. To overcome these hurdles, an enterprising company has introduced a revolutionary impact crusher machine that promises to address these challenges head-on.Key Features and Benefits:This innovative impact crusher machine boasts several key features that set it apart from its competitors. First and foremost, it incorporates advanced crushing technology that ensures superior reduction ratios and consistent product gradations. This improved efficiency not only translates into higher production capacity, but also reduces the amount of energy consumed, contributing to a greener and more sustainable operation.Furthermore, this impact crusher comprises a robust and durable construction, utilizing high-quality materials to withstand heavy-duty applications. With enhanced reliability and durability, this machine is designed to endure the demanding conditions associated with aggregate processing, reducing downtime significantly and enabling uninterrupted production.Notably, the impact crusher's intelligent control system provides operators with real-time data and alerts, ensuring safe and efficient operation. Equipped with various sensors and monitoring devices, the machine automatically adjusts its settings to optimize performance and prevent any potential equipment malfunctions. This state-of-the-art technology not only improves safety for operators but also protects the investment of aggregate producers.Additionally, the impact crusher machine offers unmatched versatility, with its adaptable configuration options. Whether processing primary, secondary, or tertiary applications, this machine can be easily adjusted to meet specific production requirements. Coupled with a user-friendly interface and intuitive controls, operators can effortlessly fine-tune the machine to achieve the desired aggregate output.Company Vision and Commitment:The company behind this revolutionary impact crusher machine has a strong commitment to innovation and excellence. With a dedicated team of engineers and experts, they strive to continuously push the boundaries of aggregate processing technology. By collaborating with industry stakeholders and understanding the evolving needs of customers, they aim to offer cutting-edge solutions that maximize productivity and profitability.By prioritizing customer satisfaction, this pioneering company ensures that the impact crusher machine is backed by comprehensive after-sales support, including technical assistance, spare parts availability, and maintenance services. This commitment to customer care reinforces their reputation as a reliable and trusted partner, solidifying the bond between the company and its valued clientele.Conclusion:The introduction of this revolutionary impact crusher machine marks a turning point in the aggregate industry, promising enhanced performance, increased productivity, and improved safety measures. With its advanced features, durable construction, intelligent control system, and adaptability, this technology is poised to redefine the way aggregates are processed. By combining innovation, reliability, and customer-centricity, the company behind this groundbreaking machine has cemented its position as a leader in the aggregate processing industry. As the future unfolds, this impact crusher machine will continue to shape the industry, fueling growth and progress in the world of aggregate production.

Top Mining Laboratory Equipment for Efficient Extraction Processes Revealed

Title: New Advanced Laboratory Equipment Revolutionizes Mining IndustryIntroduction:Mining Laboratory Equipment, a leading provider of cutting-edge mining equipment, has recently unveiled its latest innovative technologies that promise to revolutionize the mining industry. With a strong emphasis on efficiency, safety, and sustainability, the company aims to address the challenges faced by miners worldwide. Through continuous research and development efforts, Mining Laboratory Equipment has succeeded in creating state-of-the-art equipment that improves productivity, reduces environmental impact, and enhances overall mining operations.Efficiency and Accuracy:With its unwavering commitment to efficiency and accuracy, Mining Laboratory Equipment has introduced a range of advanced laboratory devices that enable rapid and precise analyses of ore and rock samples. The company's new compact spectrometers employ advanced spectroscopic techniques, allowing for real-time analysis of various elements present in the samples. Moreover, the integration of automated data processing algorithms significantly reduces analysis times while maintaining high levels of accuracy and reliability, saving valuable time and resources for mining companies.Safety and Occupational Health:Recognizing the crucial importance of safety in the mining industry, Mining Laboratory Equipment has implemented leading-edge safety features in its equipment. The company's improved gas detection devices utilize highly sensitive sensors, capable of detecting even the slightest traces of potentially hazardous gases in mining sites. By providing early warnings, these devices minimize the risk of occupational accidents, ensuring the well-being of miners working in potentially dangerous environments. Additionally, state-of-the-art ventilation systems have been developed to ensure proper airflow in mines, preventing the buildup of harmful gases and improving overall air quality.Sustainability and Environmental Consciousness:Addressing the growing demand for sustainable mining practices, Mining Laboratory Equipment has developed environmentally friendly solutions that minimize the industry's ecological footprint. The company's advanced water treatment technology aims to reduce water usage in mining operations significantly. Integrating efficient purification systems and innovative recycling techniques, miners can reuse water resources, thereby conserving scarce freshwater supplies and contributing to sustainable water management practices.In addition, Mining Laboratory Equipment is committed to reducing the emission of greenhouse gases associated with mining operations. The company's cutting-edge dust control systems effectively capture and neutralize particulate matter and other hazardous airborne pollutants. By minimizing air contamination, these systems enhance the air quality surrounding mining sites and minimize the impact on local ecosystems.Collaborative Approach and International Partnerships:Mining Laboratory Equipment understands the importance of collaboration and partnership in addressing the complex challenges faced by the mining industry. The company actively engages with miners, regulators, and stakeholders to gain insight into their specific needs and requirements. Through strategic partnerships with leading mining corporations, academic institutions, and research organizations, Mining Laboratory Equipment continues to enhance its technological capabilities and develop customized solutions tailored to the unique demands of mining operations worldwide.Conclusion:Mining Laboratory Equipment's latest technological advancements mark a significant milestone in the mining industry, offering improved efficiency, heightened safety, and enhanced sustainability. By introducing state-of-the-art laboratory devices, the company empowers miners to make informed decisions based on rapid and accurate analyses. Moreover, by emphasizing safety and occupational health through the integration of advanced gas detection and ventilation systems, Mining Laboratory Equipment is at the forefront of promoting a safer work environment for miners globally.As the mining industry increasingly embraces sustainable practices, Mining Laboratory Equipment's commitment to reducing water usage and minimizing greenhouse gas emissions demonstrates its dedication to environmental stewardship. Through collaborative efforts, the company continues to strengthen partnerships with key industry players, ensuring its solutions are at the forefront of mining technology.With Mining Laboratory Equipment's groundbreaking technologies, mining companies can operate more efficiently, meet stringent safety standards, protect the environment, and contribute to a sustainable future for the industry.

Powerful Impact Crusher With High Efficiency - The Ultimate Solution for Crushing

Impact crusher Pf1010 named to be removed is the latest addition to the product line of a well-known industry player in the field of machinery. The company has been providing state-of-the-art machines to various businesses for over a decade now and has established itself as a reliable and trustworthy brand.The new impact crusher is designed to meet the needs of businesses dealing with the production of high-quality aggregates, with a focus on energy efficiency and ease of use. It boasts a robust build quality, with a rugged steel body that ensures durable performance and longevity.The Pf1010 features a powerful rotor with a diameter of 1000 mm, which ensures maximum productivity and efficiency. The rotor is made of high-quality materials, which provides exceptional strength and durability, even when operating in harsh and demanding conditions.One of the key features of this impact crusher is its ability to adjust the output size of the finished product. This is made possible by the adjustable gap between the impact plate and the hammer plate, which allows for fine-tuning of the final product size.The Pf1010 also comes equipped with a variety of safety features, including a hydraulic opening mechanism that allows for quick and easy access to the interior of the machine for maintenance and cleaning. The machine is also equipped with an automatic overload protection system, which ensures the safety of both operators and the machine itself.The company behind this new machine has an excellent track record of providing exceptional customer service and support, with a team of highly trained and experienced technicians and engineers on hand to assist with any maintenance or technical issues that may arise.Furthermore, the company has established a reputation for delivering products that are not only of high quality but also competitively priced. This makes the Pf1010 a compelling choice for businesses looking to upgrade their machinery without breaking the bank.In conclusion, the Pf1010 impact crusher is a top-of-the-line machine that is designed to meet the needs of businesses dealing with the production of high-quality aggregates. With its robust build quality, exceptional productivity, and ease of use, it is a reliable and efficient machine that is sure to deliver outstanding performance for years to come. Backed by a company known for its exceptional customer service, the Pf1010 represents an excellent investment for businesses looking to upgrade their machinery.

Highly Efficient Jaw Rock Crusher: Top-Notch Crushing Performance Unleashed!

In the world of manufacturing and construction, innovation is key. One of the most groundbreaking inventions in recent times is the jaw rock crusher, a machine designed to crush massive rocks into smaller pieces. It has revolutionized the way construction and manufacturing companies operate. With this revolutionary machine, construction and manufacturing companies now have the ability to process large quantities of materials in a shorter amount of time, leading to increased productivity and efficiency.One of the leaders in the manufacture of jaw rock crushers, the company specializes in producing high-quality machinery that is used in the construction and mining industries. Their jaw rock crusher boasts several features that make it a must-have machine for construction and mining companies. These features include:1. High Crushing Ratio: The crusher has a higher crushing ratio compared to other crushers, making it ideal for crushing hard rocks and ores.2. Easy Maintenance: The crusher is designed with ease of maintenance in mind, reducing downtime and prolonging the lifespan of the machine.3. High Efficiency: The machine is designed to work efficiently and reliably in demanding conditions.4. Low Energy Consumption: The jaw rock crusher is designed to use minimal energy, making it ideal for large-scale operations.5. Environmental Friendly: The crusher has a low carbon footprint and is built to meet the highest environmental standards.The company has a well-equipped manufacturing facility that enables them to produce high-quality machines that meet the needs of their clients. Their team of engineers and technicians work tirelessly to ensure that their machines are of the highest quality and are built to last. All machines are rigorously tested to ensure that they meet the exact specifications of their clients.With over a decade of experience in manufacturing jaw rock crushers, the company has established itself as a reliable and reputable manufacturer in the industry. They have a proven track record of producing high-quality machines that meet the needs of their clients.But beyond the quality of their machines, the company is also dedicated to providing excellent customer service. They understand that their clients' success is their own success, so they go above and beyond to ensure that their clients are satisfied with their machines. Their team of customer service representatives is always ready to assist clients with any queries or technical issues they may have.In recent years, the demand for jaw rock crushers has increased significantly, as construction and mining companies seek to improve their productivity and efficiency. The company has risen to the occasion, providing machines that meet the needs of their clients and exceed their expectations.The jaw rock crusher has proven to be an essential machine in the construction and mining industries. It has revolutionized the way construction and mining companies operate, making it easier and more efficient to crush large quantities of materials in a shorter amount of time.In conclusion, the jaw rock crusher has become an integral part of the construction and mining industries. With its high crushing ratio, easy maintenance, high efficiency, low energy consumption, and environmental friendliness, it has proven to be a reliable and efficient machine. And with companies like this manufacturing high-quality machines, the construction and mining industries can look forward to increased productivity and efficiency in the years ahead.

Benefits of Using Crushing Equipment for Construction Projects

Rock Breakers and Crushers – The Ultimate Mining Equipment Mining is the backbone of many economies around the world, and the need to extract minerals and resources has only grown over time. As such, the need for efficient and reliable equipment in the mining industry has been on the rise. One such equipment is the rock breaker and crusher, which have been instrumental in breaking down rocks and minerals efficiently, increasing productivity, and reducing costs. Rock breaker and crusher equipment have been around for commercially viable purposes since the early 19th century, and with advancements in technology, these machines have become more reliable and efficient in their operations.One such company that has been at the forefront of designing and manufacturing rock-breaking equipment is (need remove brand name). This company has been in the business of providing high-quality equipment for over a century, with a vast selection of mining equipment that serves different applications in the industry. They understand the complexities and demands of the mining industry, and as such, they have invested in research and development to come up with some of the most advanced rock-breaking technology.Their rock crushers are some of the most efficient on the market, engineered to crush materials into smaller sizes with minimal effort. These machines come in various sizes, shapes, and capacities, with the ability to handle different types of rocks, ores, and minerals. Their jaw crushers, for instance, come in three types - Single toggle jaw crushers, Double toggle jaw crushers, and Blake crushers. The single toggle jaw crusher is suitable for finely crushing small particles, while the double toggle crusher is designed for larger ones. Blake crushers are designed for crushing tough and abrasive materials in the mining industry.In addition to jaw crushers, this company offers various other types of crushers such as gyratory crushers, impact crushers, and cone crushers, all engineered to help mines extract minerals efficiently. Their cone crushers are some of the most advanced, designed to crush even the hardest rocks with minimal wear and tear. These machines are equipped with hydrostatic bearings, providing reliable and long-lasting performance. Besides crushers, (need remove brand name) also provides rock breaker equipment, which is used to break down large rocks and minerals into smaller, more manageable sizes. These machines are usually fitted to existing excavators, and depending on the size of the job at hand, the breaker heads come in a range of sizes and weights. The company's rock breakers are engineered to work efficiently, minimizing downtime while also improving productivity.In conclusion, any mining operator worth their salt will tell you that efficient and reliable equipment is crucial in the mining industry. And while there are many brands, (need remove brand name) stands out for its dedication to research and development of advanced mining equipment. Whether it's through their crushers or rock breakers, mines across the world are able to extract resources more efficiently and cost-effectively thanks to (need remove brand name)'s contribution. It's no wonder their equipment is in demand by mining companies globally.About (need remove brand name):For over a century, (need remove brand name) has been at the forefront of providing advanced mining equipment for mining operators globally. From their efficient and reliable rock-breaking equipment like crushers and rock breakers to a wide range of other high-quality mining equipment, (need remove brand name) is the go-to brand for mining companies worldwide. The company is dedicated to providing high-quality equipment backed with exceptional customer service to ensure customer satisfaction.

Effective Charcoal Crushing Techniques to Boost Production and Efficiency

Title: Innovative Charcoal Crushing Technology Revolutionizes the Charcoal Industry Introduction:In a bid to revolutionize the charcoal production process, a leading company in the field has recently introduced an innovative charcoal crusher. This groundbreaking technology aims to significantly improve the efficiency and quality of charcoal production, bringing about positive environmental and economic impacts. By removing the brand name from the equation, we will delve into the features and potential benefits this charcoal crusher offers to the industry.I. Background and Challenges in Charcoal Production:Charcoal production plays a vital role in a range of industries such as cooking, heating, and metallurgy. However, traditional charcoal production methods often involve inefficient procedures, high carbon emissions, and low-quality output. These challenges have spurred the need for advanced technologies to optimize the charcoal manufacturing process.II. Introduction to the Innovative Charcoal Crusher: The newly developed charcoal crusher utilizes state-of-the-art technology to achieve a clean and efficient method of producing charcoal. By employing cutting-edge crushing techniques, this equipment aims to enhance the combustion efficiency and overall quality of charcoal, while minimizing the impact on the environment.1. Crushing Mechanism:The charcoal crusher employs a unique crushing mechanism that ensures uniform particle sizes, efficient grinding, and high reliability. With adjustable settings, the charcoal crusher enables operators to produce custom-sized charcoal to suit specific market demands.2. Efficient Energy Utilization:Equipped with an advanced power system, the charcoal crusher efficiently consumes energy during the crushing process. This feature not only reduces the operating costs for charcoal manufacturers but also minimizes the overall carbon footprint associated with charcoal production.III. Key Benefits and Impacts:1. Enhanced Profitability and Market Competitiveness:The innovative charcoal crusher allows manufacturers to produce high-quality charcoal products, in turn, increasing their profitability and market competitiveness. The ability to meet market demands by providing uniform-sized charcoal will undoubtedly attract more consumers and business partners.2. Environmental Sustainability:The charcoal crusher's advanced technology aids in reducing the overall greenhouse gas emissions produced during the charcoal manufacturing process. The improved combustion efficiency results in fewer harmful pollutants being released into the atmosphere, thereby promoting a cleaner and healthier environment.3. Improved Ergonomics and Efficiency:The efficient design of the charcoal crusher significantly improves the productivity and user experience. The adjustable settings and easy maintenance procedures offer enhanced convenience and promote a safer working environment for operators.4. Economic Growth and Job Creation:The adoption of this innovative charcoal crusher can stimulate economic growth by creating employment opportunities in the production and maintenance associated with the equipment. The increased efficiency and quality of charcoal production will also strengthen the industry's contribution to the national economy.IV. Future Prospects for the Charcoal Crusher:The introduction of an innovative charcoal crusher signifies a crucial step towards modernizing the charcoal production industry. With continuous research and development, industry experts anticipate further improvements in energy efficiency, production capacity, and overall sustainability.Conclusion:The introduction of the charcoal crusher unveils a transformative chapter in the charcoal production industry. By combining state-of-the-art technology, efficient energy utilization, and sustainable practices, this innovative device promises enhanced profitability, reduced environmental impact, and improved working conditions for charcoal manufacturers. As demand for high-quality charcoal continues to rise, embracing such advanced technologies will undoubtedly shape a more sustainable and prosperous future for the industry.